Clarifier Operation

Operating Principle

The Locker Clarifier System operates on the principle of cake filtration to reduce suspended solids carry over, with the filter mesh media upon which the cake is formed having a high open area of 61%.

This minimises differential pressure and enables the screens to handle higher hydraulic loadings, typically 1.67 m3/m2/hr for end-flow and pyramidal (Dortmund) type tanks, and up to 5 m3/m2/hr for radial tanks fitted with the Locker Auto-Cleaner.

Locker Clarifier Systems are designed to reduce suspended solids carry over in:

- Upward flow clarifiers

- Radial clarifiers

- Endflow tanks

- Pyramidal tanks

Synthetic clarifier mesh

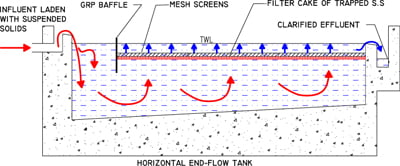

Horizontal End Flow Tank Schematic

The performance of the settlement tank is improved by the clarifier screens as follows:

- The uniform distribution of the numerous apertures of the precision filter mesh equalises the hydraulic loading over the entire area of the screens, this enhances natural settlement of the larger, denser solids particles and attenuates the effect of upwelling currents at the weir.

- The less dense particles of rising suspended solids converge as they approach the apertures of the mesh and flocculate to form a filter cake on the underside of the screen panels. This filter cake retains fine solids which would otherwise be discharged into the weir channel.