Woven Wire Mesh for EMI / RFI Shielding

We live in a digital world, filled with an ever-increasing number of electronic devices. This, coupled with demanding Electromagnetic Compatibility (EMC) Engineering regulations, has resulted in increasing demand for EMI / RFI shielding materials.

Locker Woven Wire Mesh is used to protect against Electromagnetic Interference (EMI) for varying applications. Mesh can be supplied as rolls, cut to size pieces, or as fabricated parts to suit individual requirements.

In the majority of cases Copper Wire mesh is recommended for EMI / RFI Shielding.

What is EMI / RFI?

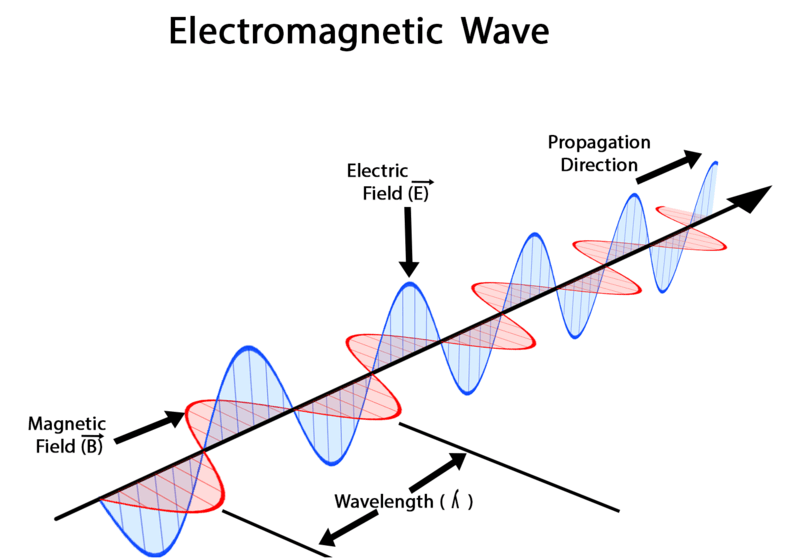

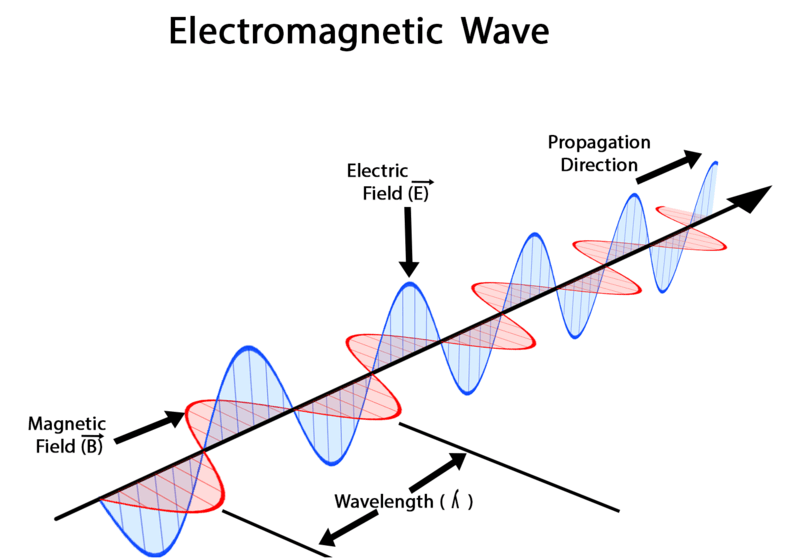

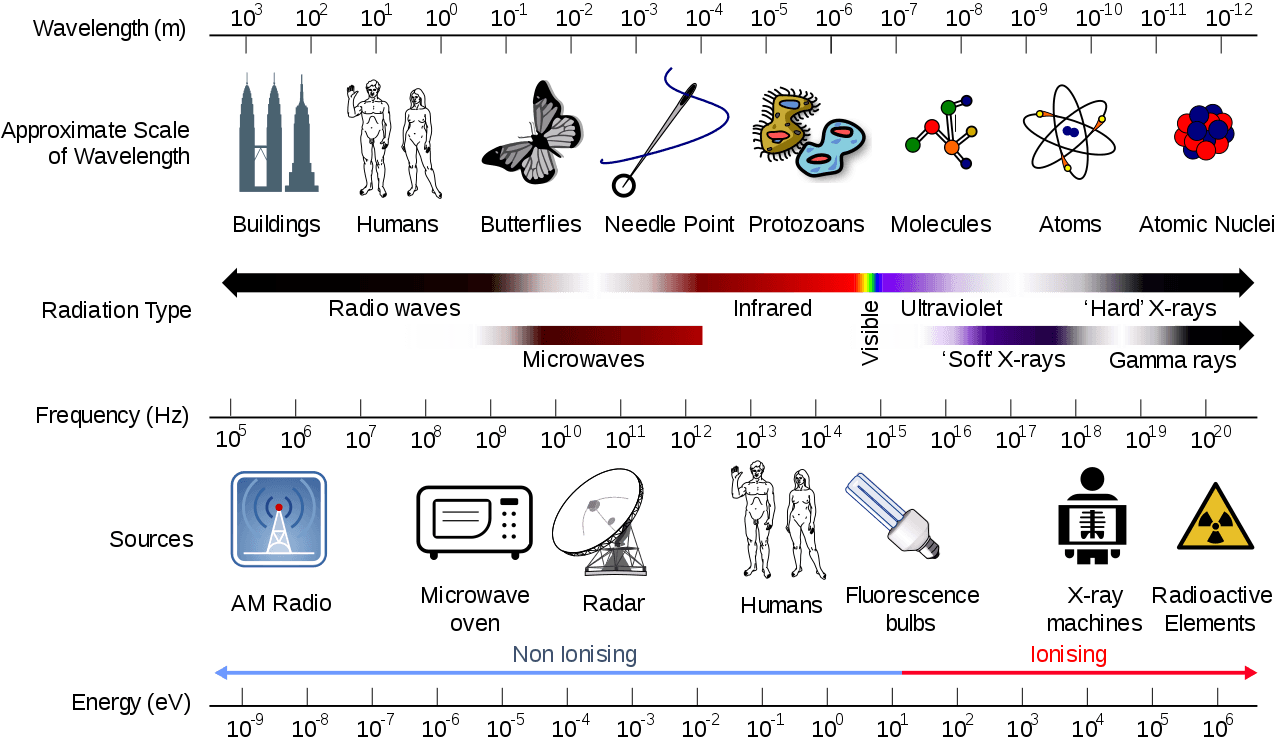

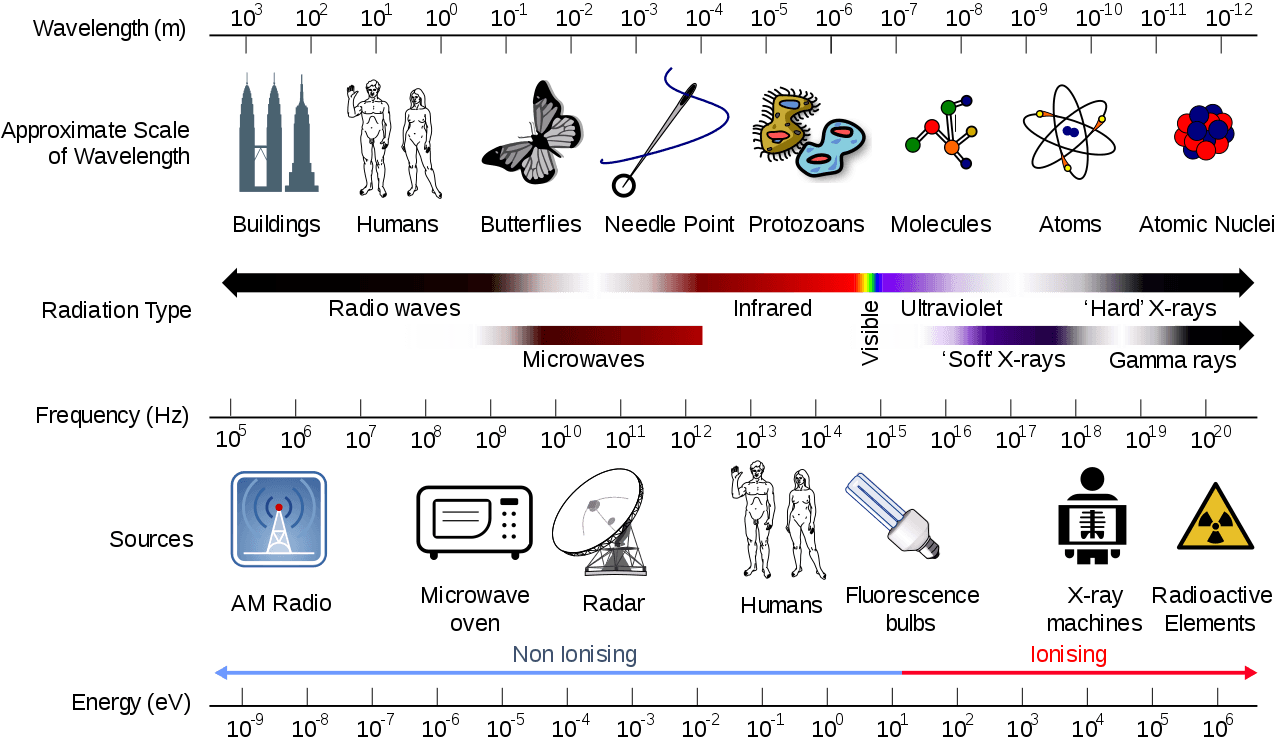

Electronic devices emit electromagnetic radiation of varying wavelengths.

Everyday sources include:

- Mobile / cellular phones

- Smart meters

- Computers and associated peripherals

- Radio transmitters

- Television broadcasts

- Microwaves

- Wi-Fi routers

- Bluetooth transmitters

- Arc welders

- Power lines

- Fluorescent lights.

Electromagnetic radiation is also emitted during natural events such as lightning or solar storms. At low levels, this radiation is not usually harmful to humans. However, it can disrupt the functionality of other electronic devices.

This phenomenon is referred to as Electromagnetic Interference (EMI), a subset of which is Radio Frequency Interference (RFI), referring specifically to EMI caused by EM radiation in the radio spectrum (frequencies between 100KHz and 300GHz).

Some EMI is merely frustrating, like the noise that occurs when a mobile phone is placed too close to audio speakers or microwaves/baby monitors that interfere with Wi-Fi signal, making internet speeds slower, or causing the connection to drop entirely.

However, in some circumstances, EMI is extremely dangerous. For example, if it were to impair the function of critical systems in any of the following industries:

- Military

- Aerospace/Avionics

- Naval

- Medical

- Telecommunications

What is EMI / RFI shielding?

Electromagnetic interference (EMI) shielding is put in place to attenuate (reduce the intensity of) RFI / EMI. Generally, a full enclosure around a component is formed using this shielding material, attenuating EM waves both leaving and entering.

In this way the shield protects the component in question from outside interference and significantly reduces any EM leakage. There are two ranges of electromagnetic shielding: Magnetic shielding and radio frequency shielding. By far the least common is of the two is Magnetic Shielding, used to protect against strong magnetic forces at low frequencies (anything below 100KHz). By utilising material with high magnetic permeability (such as Mu-metal or iron/steel), magnetic shielding attracts and then redirects magnetic fields away from whatever is being shielded. Strong magnetic forces are typically prevalent in areas with strong electric current, such as power plants or transformer rooms. These magnetic forces can be damaging to the health of a human. High frequencies (anything above 100KHz) require “Radio Frequency” shielding. Radio Frequency shielding utilises materials with high conductivity with very little magnetic permeability (such as copper mesh) to apply the Faraday effect to EM waves. All instances of EMI RFI listed in the earlier section are in the radio frequency range.

When should you use EMI / RFI Shielding?

EMI / RFI shielding should be used in all the critical systems mentioned earlier, but there are also many other applications. Consumer electronic devices, sometimes referred to as PED’s (personal electronic devices) utilise EMI shielding to reduce any EMI from other nearby electronics, as well as prevent any EM leakage which could affect other electronics. The management and design of these systems are a subset of electrical engineering referred to as EMC Engineering. MRI rooms in hospitals are encased in shielding to prevent any RFI from distorting the images being produced. Shielding can even be used to line rooms in order to limit the use of mobile phones! Entire buildings are sometimes encased in electromagnetic shielding in order to prevent the emission or intrusion of EM radiation. For example, governments may choose to encase their foreign embassies in EMI shielding to prevent spying. Some keyboards emit EM radiation with every keystroke, which can be monitored from distances of up to 20m. If you don’t believe it, ask Gene Hackman, In the film Enemy of the State, he plays a former intelligence agent, who masks his electronic activities from the intelligence community via the clever installation of copper wire mesh as EM shielding. Other applications include:

- Shielding of testing rooms / laboratories

- Protection of electronics against Nuclear electromagnetic pulse (EMP)

- Prevention against Radio Frequency Identification (RFID) skimming. This could be contactless credit/debit cards or other wireless electronics such as car keys, laptops of mobile phones etc.

- Signal jamming / stealth technology (radar energy absorption)

- NFC (Near Field Communication) blocking

Why is Copper Mesh used for EMI / RFI Shielding?

Copper woven wire mesh has long been established for use as EMI / RFI shielding - ever since Michael Faraday, one of most notable scientists who ever lived, discovered the Faraday cage. But what is it about copper mesh that makes it so effective?

View copper wire mesh specifications used for EMI /RFI Shielding

Material Properties

The majority of EMI / RFI shielding works best with highly conductive material.

Copper has excellent thermal and electric conductivity, but not as good as silver.

Silver is in fact the most conductive naturally occurring material. So, from that perspective only, it should theoretically be the best material for creating an EMI / RFI shield.

We use copper due to its more favourable price, availability and malleability (the ease with which it is woven into a mesh and manipulated into different shapes).

Silver

Copper

Gold

Aluminium

Carbon Steel

Stainless Steel

6.30×107

5.96×107

4.1×107

3.77×107

6.99×106

1.45×106

Mesh Properties

Woven Wire mesh is a flexible product which can be tailored to suit your requirements.

- Wire mesh can be manipulated easily to suit all manner of complex shapes and sizes, without compromising its structural integrity.

- When wire mesh is fabricated using the correct material, and the aperture of the mesh is significantly smaller than the wavelength of the EMI, then the strength of passing EM waves is significantly reduced. However, this does not always behave in a linear fashion! Luckily, the actual specification of wire mesh (aperture and wire diameter) can easily be tailored to best attenuate the interference frequency range/s in question.

- Spontaneous corona discharges happen in high-voltage systems. Transient current pulses produced by corona discharges result in EMI of varying frequencies. Woven wire mesh assists in avoiding this negative ‘Corona Effect’ by dissipating electrostatic charge.

- Copper Wire mesh is also easy to see through, which makes it ideal for use in windows and as optical filters in computer screens etc.

What are optical filters?

EMI / RFI shielding mesh is split into two categories - optical grade and non-optical grade. Optical grade material is used in windows, display screens etc. The mesh is laminated between various substrates and adhesives in a clean room to prevent any contamination. Optical grade material must be highly transparent, non-reflective and homogenous – as the eye is quickly drawn to any irregularities. In order to reduce reflectiveness, the mesh is often blackened. This is not to be confused with mesh for an optical filter. Optical filters filter out light of different wavelengths.

How can you measure the effectiveness of EMI shielding?

It is a common misconception that EM shielding completely eradicates EM radiation. The intensity of an EM wave is measured in Watts. EMI shielding reduces the signal intensity of electromagnetic waves passing through it. The degree to which it does this is referred to as the attenuation and is measured in Decibels (dB) on a logarithmic scale (base 10). i.e. A reduction in signal intensity by a factor of ten (10x) is a 10dB attenuation. A reduction in signal intensity by a factor of 100x is 20dB of attenuation, etc. Therefore, if a radio wave is measured at 20 milliwatts before shielding, and then 2 milliwatts after passing through shielding, then there is 10dB of attenuation. If the wave goes from 20 milliwatts to 0.2 milliwatts then there is 20dB of attenuation. 20 milliwatts to 0.02 milliwatts is 30dB, and so on. Care should be taken when companies claim to offer materials which “shield 99% of EM radiation”.

A range of frequencies should always be specified along with any claim. Without the frequency range the claim applies to, the material could be useless against the EMI frequency you are trying to shield against! Secondly, 99% shielding is only 20dB of attenuation. Across many applications, the minimum attenuation acceptable is generally 99.99% shielding. i.e. 40dB of attenuation. People often assume that a product which offers 40dB of attenuation is twice as good as 20dB of attenuation. This is not the case, it is in fact 100x better. The actual level of attenuation is measured using an EMF meter. First a signal strength baseline is determined without shielding in place, then a second signal strength measurement is taken with the shielding in place. You will need a meter that measures the correct electromagnetic subset, magnetic, or EM / radio frequency. Any claims presented as facts should be based on tests undertaken by independent experts who were conducted testing off site.