Wire Mesh for Catalyst Support and Separator Screens

Circular woven wire mesh screens are used for a range of industrial processes and, depending on the application, can also be referred to as 'Catalyst Support and Separator Screens' , 'Floating Screens', 'Gas Dehydrator Screens', 'Gas Drier Screens', 'Gas Dryer Screens' or 'Molecular Sieve Support Grid Screens'.

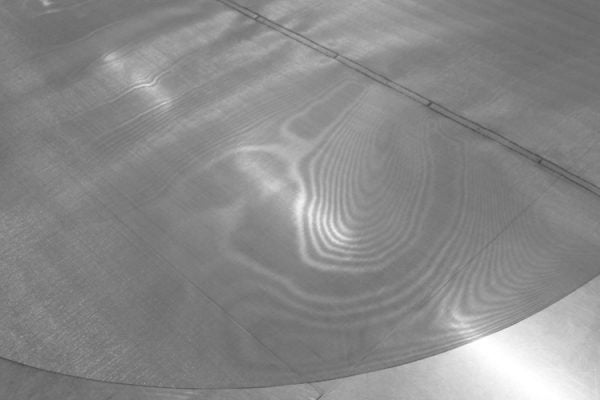

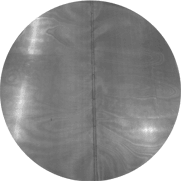

Most Locker wire mesh screens are supplied custom cut, sized and seam welded to achieve the precise width and mesh specification required.

They can also be shipped as single piece discs, on a roll or in separate cut-to-size sections.

Locker Wire Weavers' bespoke precision engineering provides customers with a quality, cost-effective solution for replacement of worn out wire mesh screens to extend the life of original, and otherwise perfectly serviceable, processing units.

Screens are built to specification using precision welded segments.

Catalyst Support and Separator Screens

For use in ammonia oxidation plant catchment packs for precious metal recovery, woven wire mesh screens are available in FeCrAl heat resistant wire mesh and a range of other alloys, depending on requirements.

Gas Dehydrator Screens

Replacement woven wire mesh Gas Dehydrator, 'Gas Drier' or 'Gas Dryer' screens are often required within hydroprocessing and gas dehydration plant vessels.

Molecular Sieve Support Grid Screens

Molecular Sieve support grid screens or 'floating mesh screens' are used as an effective and economic divider between the different media layers needed in reactor distillation equipment.

These screens are usually made by tying overlapping segments together inside the vessel with wire. The segments are intentionally cut oversized compared to the vessel diameter, effectively sealing the edges.