Wire Mesh for Plastic Extruder Screens and Filters

Plastic extruder screens are used to filter out impurities from the plastic melt during the extrusion process. The screen is placed in the extruder barrel or at the die entrance, and acts as a barrier between the plastic melt and the die. These filters are made from stainless or mild steel mesh and are typically constructed in one of the 3 styles shown below.

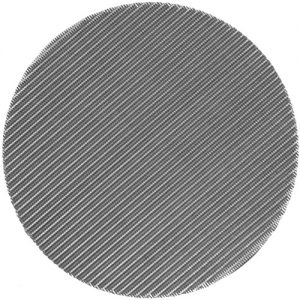

Single Screen Filters

Our wire mesh single screen filters are often used in the plastic reclamation industry, possibly with a Dutch Weave filter used with a plain weave support filter.

These are also used in the extruded profiles and blown film industries where the contamination of the raw material is less and there is often lower pressure within the extruder head.

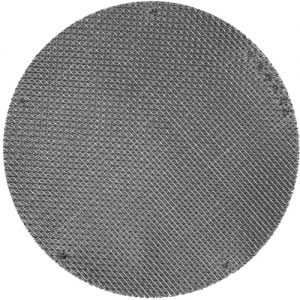

Spot Welded Filter Packs

Locker spot welded wire mesh filter packs are excellent in any field where a specific graduation filtration is required.

Another advantage is that it stops single screen filters being placed into the extruder incorrectly. For example a pack consisting of three meshes could consist of a 10mesh / 20mesh / 10mesh; meaning that whichever way the wire mesh filter is placed into the extruder head, it will work correctly.

Rimmed Mesh Filters

Locker wire mesh filter rim packs feature spot-welded packs with an Aluminium or Stainless Steel rim added for extra rigidity and strength.

These are excellent for use where the extruder screen filter is operating at high pressures or if there is a danger of contamination getting around the edge of the breaker plate.

Plastic Extruder Screens and Woven Wire Mesh Filters made from Locker wire mesh have many extrusion applications within the plastics industry. Some examples are:

- Reclamation of Plastic Waste

The recycled plastic recovered from post-consumer waste is in ever increasing demand. This is due in part to the costs of landfill and the consumers' desire for more eco-friendly products. The new plastic 'raw' material is gained by heating waste plastic and passing it through an extruder screen filter within a plastic extrusion machine. The extruder screen filter removes contaminants such as paper, allowing the clean recycled plastic to be collected at the end of the process. This can then be manufactured into a new product which has reduced the negative impact of using new plastic material. - Extruded Profiles

Wire mesh extruder screen filters are extensively used in the extrusion of plastic profiles. Applications include UPVC window profiles, plastic tubing ranging from gutters to industrial utility pipes and custom made extrusions. - Blown Film Extrusion

Extruder screen filters are used in the production of polythene bags, waste sacks and plain 'cling' film to name but a few. The wire mesh extrusion filters are an essential part of this process as they remove any remaining impurities in the plastic so that the end product does not have any flaws in it.

Our high speed machinery, coupled with an extensive range of standard disc sizes, enables us to offer a wide variety of industrial wire mesh extruder screen filters. We also stock filter belts for use in automatic screen changers.

View table of Standard Disc Sizes

View table of Standard Stock Specifications

View table of Dutch Weave Specifications

These diameters can be supplied in all of our Standard Stock Specifications as well as the range of Dutch Weaves in both stainless and plain steel where applicable.

Most of the standard disc sizes used in extrusion and filtration processes are available from existing die sets. A table listing these sizes is provided via the link below.

Dedicated tooling to press custom-made components can be manufactured to order.

Extruder screens, disc packs and spinneret filters

Other facilities include the high speed cutting of plain discs and washers, together with a variety of shaped woven wire mesh screens. These can be supplied as separate components or combined in varying meshes, spot welded together or bound with aluminium, stainless steel or copper rims to form multi-layer screen packs and spinneret filters. This range of products is supplied extensively for use in the manufacture and reprocessing of plastic and rubber products and to the synthetic fibre industry.

Multi-layer tubular screens for plastic extrusion equipment and high tensile stainless steel mesh bands for use in automatic screen changers are also available.

Other finishing services available include:

- Slit to width rolls

- Cut pieces

- Fine blanking

- Annealing

- Degreasing

- Ultra sonic cleaning

- Calendering

- Air plasma cutting

- Laser cutting of complex shapes

Locker have decades of experience in supplying wire mesh sheet, rolls and complete filter assemblies for use in plastic extrusion. Please contact our sales team to discuss your specific requirements.