Woven Wire Mesh Weave Types

Locker supply all types of woven wire mesh. The most commonly used wire mesh weaves are shown below:

(Standard Stock Specifications)

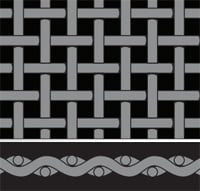

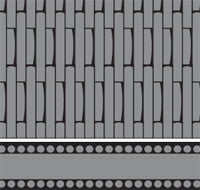

Plain Weave

Plain weave woven wire mesh is used for the majority of wire mesh woven by Locker. Each warp wire crosses alternately above and below every weft wire and vice versa. Warp and weft wires are normally of the same diameter.

Plain weave woven wire mesh is used for the majority of wire mesh woven by Locker. Each warp wire crosses alternately above and below every weft wire and vice versa. Warp and weft wires are normally of the same diameter.

Used for the majority of commercial applications and for filtration where a high flow rate is required.

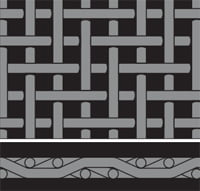

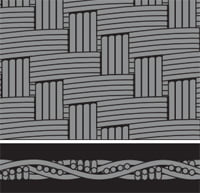

Twill Weave

Each weft wire passes alternately above and below every successive pair of warp wires and vice versa.

This weave permits a heavier wire diameter to be used than would be possible in a plain weave wire mesh with similar mesh count.

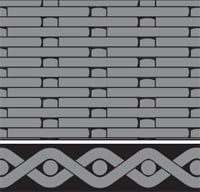

Dutch Weave

Dutch or 'Hollander' Weave is a description applied to woven wire mesh where the diameter of the warp and weft wires, and the mesh count in the warp and weft directions, are different. The wires are driven up much closer during the weaving process, thus producing a more densely compacted media.

Mesh count per inch and aperture size in microns are the most commonly used methods of describing the various Dutch Weave wire mesh specifications.

We offer four standard weave types, all available in Stainless Steel.

Plain Steel, Monel and non-ferrous alloys are available in a limited number of specifications.

Plain Dutch Weave

Woven as a plain weave, but with the warp wires of greater diameter than the weft wires.

The weft wires are woven tightly together producing a strong wire cloth whilst allowing a good flow rate.

Twill Dutch Weave

Similar to Plain Dutch Weave, but effectively has a double layer of weft wires woven in twill pattern.

This wire mesh is "light tight", has a very smooth surface, is strong, but has a restricted flow rate.

Also referred to as Micromesh wire cloth and is used for critical filtration applications often under high pressure.

Reverse Dutch Weave

Normally woven as a plain weave, but in reverse manner to Plain Dutch Weave. The weft wires are of greater diameter than the warp wires, and consequently the warp mesh count is greater than the weft mesh count.

This woven wire mesh is extremely strong, is easily cleaned and has a high flow rate.

Also known as Robusta.

Absolute Micron Retention

In all types of Dutch Weave, the sum derived from multiplying the number of weft wires in a given measurement by their diameter, results in theory, in a specification with no open space. Because the wires are driven together during the weaving process, the aperture size cannot be calculated in the normal manner.

There are two methods by which the wire cloth aperture size can be determined:

BUBBLE POINT TEST

The pressure required to pass air bubbles through the mesh (covered by a test liquid) is measured. The average aperture size is then calculated by taking into account surface tension, liquid density, temperature and immersion depth.

GLASS BEAD TEST

A suspension containing glass beads is passed through the wire mesh - the diameter of the largest bead passing through is considered as the absolute micron retention.

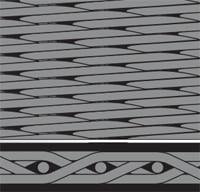

Multiplex Weave

A Twill Weave wire mesh but with multiple wires making up warp and weft.

A strong wire mesh with a relatively high number of openings per unit area, and considerable flexibility.

In certain constructions it can produce capillary action.