ISO 4783-1 is the international standard relating to the choice of aperture size and wire diameter combinations.

Wire Mesh Designations

MESH No.

The wires running lengthways during manufacture are referred to as warp wires, and the wires that run across the width of the mesh are referred to as weft or shoot wires.

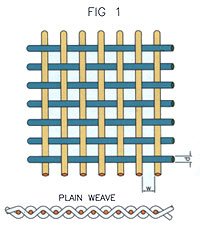

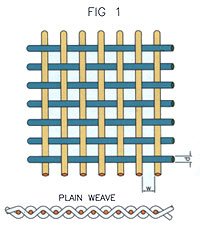

PLAIN WEAVE (PW).

Each weft wire passes over one and under one warp wire, and each warp wire passes over one and under one weft wire. (See Figure 1).

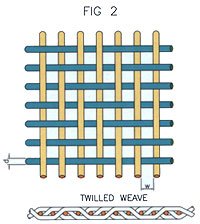

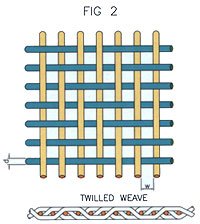

TWILL WEAVE (TW).

Each weft wire passes over two and under two warp wires, and each warp wire passes over and under two weft wires. (See Figure 2).

APERTURE WIDTH (w).

The distance between two adjacent warp or weft wires measured in the projected plane at mid positions.

The aperture width (in mm) is calculated according to the following equation:

![]()

![]()

Aperture size and wire diameter calculations are according to ISO 4783-2

Open Screening Area (Ao)

Percentage of the surface of all the apertures in the total screening surface calculated using the following equation:

![]()

![]()

Mass per unit area (kg/m2)

The nominal mass per unit area can be calculated from the following equation:

Our metal mesh calculator may also be used to calculate mesh aperture size, percentage open area and the weight per square metre, from mesh count and wire diameter.

Standard metal and alloy availability

The table below gives a general guide to the standard materials available and their associated wire diameter limitations.

Available Wire Mesh Materials & Associated Limiting Wire Diameters

Type of Material | Limiting Wire Diameter |

| Stainless Steel 304, 316 and low carbon grades | All specifications |

| Stainless Steel High Tensile (For Reverse Dutch Weaves) | 0.20mm |

| Plain or Mild Steel | 0.132mm |

| Galvanised Mild Steel | 0.17mm |

| Aluminium | 0.224mm |

| Copper | 0.05mm |

| Brass | 0.04mm |

| Phosphor Bronze | 0.035mm |

| Pure Nickels & Alloys | 0.035mm |

| Pure Silver | All specifications |

| *Monel 400 | 0.04mm |

| *Incoloy, Inconel Heat Resistant Specifications | 0.112mm |