Woven Wire Mesh Products

Locker has a wide variety of skills, capability and equipment for the manufacture of finished components, filters and screens in many forms.

Fabricated Filters

Locker manufacture purpose-made filters, pressings and filter elements to customers' specifications. Facilities include welding, soft soldering, brazing, spot welding and press forming, and the production of filters incorporating turned or shaped metal components.

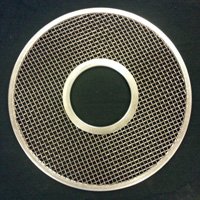

Extruder screens, disc packs and spinneret filters

Other facilities include the high speed cutting of plain discs and washers, together with a variety of shaped screens. These can be supplied as separate components or combined in varying meshes, spot welded together or bound with aluminium, stainless steel or copper rims to form multi-layer screen packs and spinneret filters. This range of products is supplied extensively for use in the manufacture and reprocessing of plastic and rubber products and to the synthetic fibre industry. Multi-layer tubular screens for extrusion equipment and high tensile stainless steel meshbands for use in automatic screen changers are also available.

Other finishing services available include:

- Slit to width rolls

- Cut pieces

- Fine blanking

- Annealing

- Degreasing

- Ultra sonic cleaning

- Calendering

- Air plasma cutting

- Laser cutting of complex shapes.