Wire Mesh for Fuel Cells and Batteries

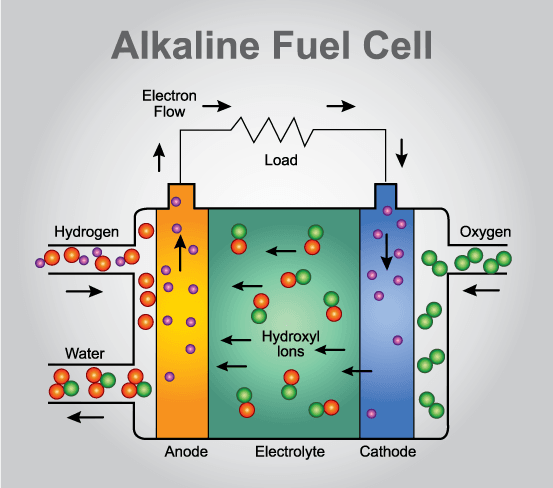

A fuel cell is an electrochemical energy conversion device that creates usable electricity from fuel via a chemical reaction. The chemical reaction, that occurs without combustion, converts hydrogen and oxygen into water. In the process electricity and heat are also created.

Fuel cell technology can be:

- Alkali

- Molten Carbonate

- Hydrogen Electrolysis

- Solid Oxide (SOFC)

- Polymer (Proton) Electrolyte (PEMF)

- Anion (Anode) Exchange Membrane (AEM water electrolysis)

This technology is a clean, efficient and reliable source of power generation commonly used within a range of portable, stationary and transport applications. These applications include simple battery chargers, domestic and commercial heating, plus power cells for electric and hybrid vehicles.

Locker metal mesh is used for a range of fuel cell applications, and can be applied to a wide variety of battery and electrical accumulator processes. The unique properties of porosity and conductivity offered by woven wire mesh mean that it can play many roles within a fuel cell including; gas distributor, current collector, anode and cathode.

Of all available metals, nickel alloy is especially effective at taking on the role of anodes and cathodes within fuel cells and batteries. Woven wire nickel mesh, usually annealed with a controlled thickness, can be used for a number of purposes in fuel cell development, but most often as a current collector and for anode and cathode construction.

Precise specifications of the nickel wire mesh, including other nickel based alloys, can be developed to suit your specific application.