In industries where mesh precision is critical, standards like ISO 4783 ensure that performance isn’t left to chance. Whether you’re filtering pharmaceuticals, separating polymers, or designing architectural panels, consistent mesh quality matters.

Key Benefits of ISO 4783-Compliant Mesh

- Ensures reliable and consistent mesh performance

- Supports critical applications in filtration, screening, and separation

- Provides globally recognised quality control standards

- Enhances traceability and manufacturing accountability

- Meets stringent demands in pharmaceutical, food, and industrial sectors

Understanding ISO 4783: The Global Standard for Woven Wire Mesh

ISO 4783 is the international standard defining tolerances, designations, and specifications for industrial woven wire mesh. It outlines acceptable variances for mesh count, aperture size, and wire diameter to maintain uniformity and performance across applications.

ISO 4783 covers:

- Mesh count tolerances (openings per inch or centimetre)

- Wire diameter limits

- Aperture size tolerances

- Inspection methods and acceptance criteria

- Dimensional and visual quality controls

This ensures consistent geometry, strength, and filtration performance — essential in sectors where precision is critical, such as disc filtration, sieving, and architectural installations.

Why ISO 4783 Compliance Matters for End Users

Assuming mesh quality can be risky. Without adherence to ISO 4783, mesh products may suffer from inconsistencies, which can result in:

- Reduced filtration or separation efficiency

- Premature component failure

- Process inefficiencies and downtime

- Non-compliance with regulatory or operational standards

ISO 4783 ensures that woven mesh products maintain strict dimensional and mechanical tolerances — guaranteeing the reliable performance demanded by regulated and technical environments.

Locker’s Commitment to ISO Standards and Quality

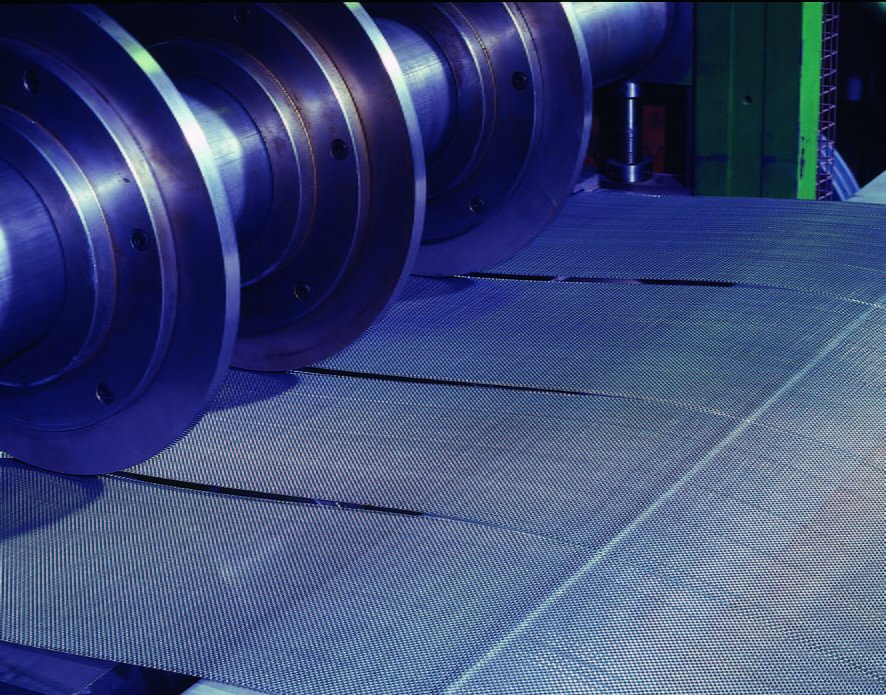

At Locker Wire Weavers Ltd, quality and precision are central to our manufacturing processes. Our compliance with ISO 4783 and ISO 9001:2015 Quality Management Systems accreditation reflects our dedication to consistent product excellence.

Locker’s quality assurance process includes:

- Inspection of raw materials using calibrated mesh counters and micrometres

- In-process quality control to monitor mesh count, aperture, and wire diameter

- Final inspections to verify compliance with ISO 4783 and customer specifications

Our trained experts ensure every batch meets international standards, offering reliable performance and full traceability.

Reinforcing Quality Through Certifications and Accreditations

Locker Wire Weavers holds globally recognised certifications that support our commitment to excellence:

ISO 9001:2015 — Quality Management Systems

- Consistent delivery of customer and regulatory requirements

- Implementation of continuous improvement

- Process-driven production controls and traceability

Our trained experts ensure every batch meets international standards, offering reliable performance and full traceability.

Mesh Tolerances and Technical Requirements for Engineers

For engineers and technical specifiers, ISO 4783 is vital. It bridges design intent and real-world application by defining mesh tolerance classes and inspection methods.

ISO 4783 outlines:

- Aperture width and wire diameter tolerances based on mesh count

- Weave classifications (plain weave, twill weave, and more)

- Inspection procedures using calibrated instruments

- Acceptance Quality Limits (AQLs) and batch sampling rules

Locker enhances this support with detailed datasheets, CAD files, and compliance certificates — streamlining validation and regulatory processes.

Filtration: The Ultimate Test of Mesh Quality

Filtration applications demand the most precise woven mesh available, especially in sectors like:

- Pharmaceuticals

- Plastics

- Industry

- Automotive

- Petrochemicals

- Food and beverage processing

- Water treatment and filtration

Critical mesh attributes include:

- Precisely controlled pore size

- Strength-to-weight optimisation

- Resistance to chemical and thermal stress

- Accurate cutting to tight dimensional tolerances

ISO 4783 provides the foundation for these strict requirements, ensuring every mesh filter delivers consistent performance and durability.

Mesh Quality in Practice: A Visual Guide

| Feature | ISO 4783-Compliant Mesh | Non-Compliant Mesh |

| Wire Diameter Tolerance | Within ± specified limits | Varies significantly |

| Aperture Consistency | Uniform and accurate | Irregular and imprecise |

| Mesh Count Accuracy | Verified per ISO 4783 | Potential inaccuracies |

| Surface Appearance | Clean and defect-free | Possible defects and inconsistencies |

| Batch Traceability | Fully documented | Unverified sources |

Precision differences like these make the difference between success and costly filtration failures.

Beyond ISO 4783: Locker’s Value-Added Mesh Solutions

While ISO 4783 defines minimum quality requirements, Locker offers enhanced solutions:

- Pre-crimped mesh for rigidity and dimensional stability

- Fine mesh for small aperture requirements

- Heat-treated mesh to relieve manufacturing stresses

- Surface coatings for corrosion resistance and food safety

- Custom mesh shapes and cuts using advanced cutting technologies

This approach meets the challenges of industries from cleanrooms to heavy-duty screening.

Industries That Depend on ISO 4783-Compliant Mesh

Food Processing

- Sieving flour, spices, and powders

- Liquid filtration solutions

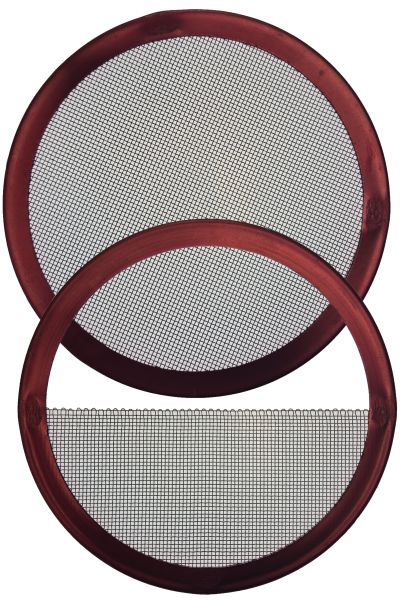

Pharmaceutical and Medical

- Sterile filtration of active ingredients

- Wire mesh drying trays and screens

- Disc meshes for fluid separation

Chemical and Petrochemical

- Catalyst support mesh

- Gas and liquid filtration

- Pressure vessel internals

Architectural and Industrial Design

- Decorative facades and infill panels

- Louvres and sunscreens

- Staircase and balustrade mesh

ISO 4783 standards help Locker deliver reliable, high-quality products across all these sectors.

FAQs: ISO 4783 and Mesh Quality

What is ISO 4783?

ISO 4783 defines the tolerances, specifications, and quality inspection methods for industrial woven wire mesh, covering mesh count, wire diameter, and aperture size.

Why choose ISO 4783-compliant mesh?

It ensures globally consistent quality, reducing risks in critical filtration, screening, and separation applications.

Is ISO 4783 compliance mandatory?

While not required by law, many industries and regulators demand it to guarantee consistent performance.

What accreditations does Locker hold to support quality?

We are certified to ISO 9001:2015 for quality management and also holds BAE approval

Can Locker supply custom mesh to ISO 4783 standards?

Yes — we manufacture bespoke mesh designs while maintaining ISO 4783 tolerances and performance requirements.

Conclusion: Quality Begins With Standards

ISO 4783 establishes the baseline for precision, reliability, and consistency in woven wire mesh production. At Locker Wire Weavers, we go further — pairing product standards with an ISO 9001:2015 accredited quality management system, and decades of expertise.

Whether for disc filtration, food processing, or architectural design, our mesh delivers unmatched performance and traceability.

Choose Locker — where ISO 4783 quality meets engineered excellence.

Content Portfolio

- AWG and SWG Wire Gauges: Conversion to mm

- Leaf Filters for Industrial Filtration

- How to Choose the Right Aperture Size for Your Application

- ISO 4783 Explained: The Global Standard for Mesh Quality and Why It Matters

- Mesh Discs and Screens for Plastic Extruders

- Wire Mesh Disc and Filter Manufacturing

- Locker Pride in Manufacturing

- Brass Mesh Lighting Pendants