Key Benefits of Choosing the Correct Aperture Size

- Enhances performance and efficiency in industrial applications

- Improves product quality by ensuring proper material selection

- Optimises cost-efficiency by preventing over- or under-specification

- Extends the lifespan of equipment and structures

- Facilitates compliance with industry standards and specifications

When specifying wire mesh for industrial uses, one of the most important decisions is selecting the correct aperture size. This term refers to the open space between adjacent wires in a mesh panel, determining how materials interact with the surface. Choosing the correct size ensures the mesh functions effectively, providing optimum filtration, screening, protection, or support depending on the application.

At Locker Wire Weavers, we specialise in high-quality woven and welded wire mesh used across multiple industries. Applications range from sieving powders in the pharmaceutical sector to screening aggregates in construction and mining. Each application demands a tailored specification — a key part of that being the appropriate aperture size.

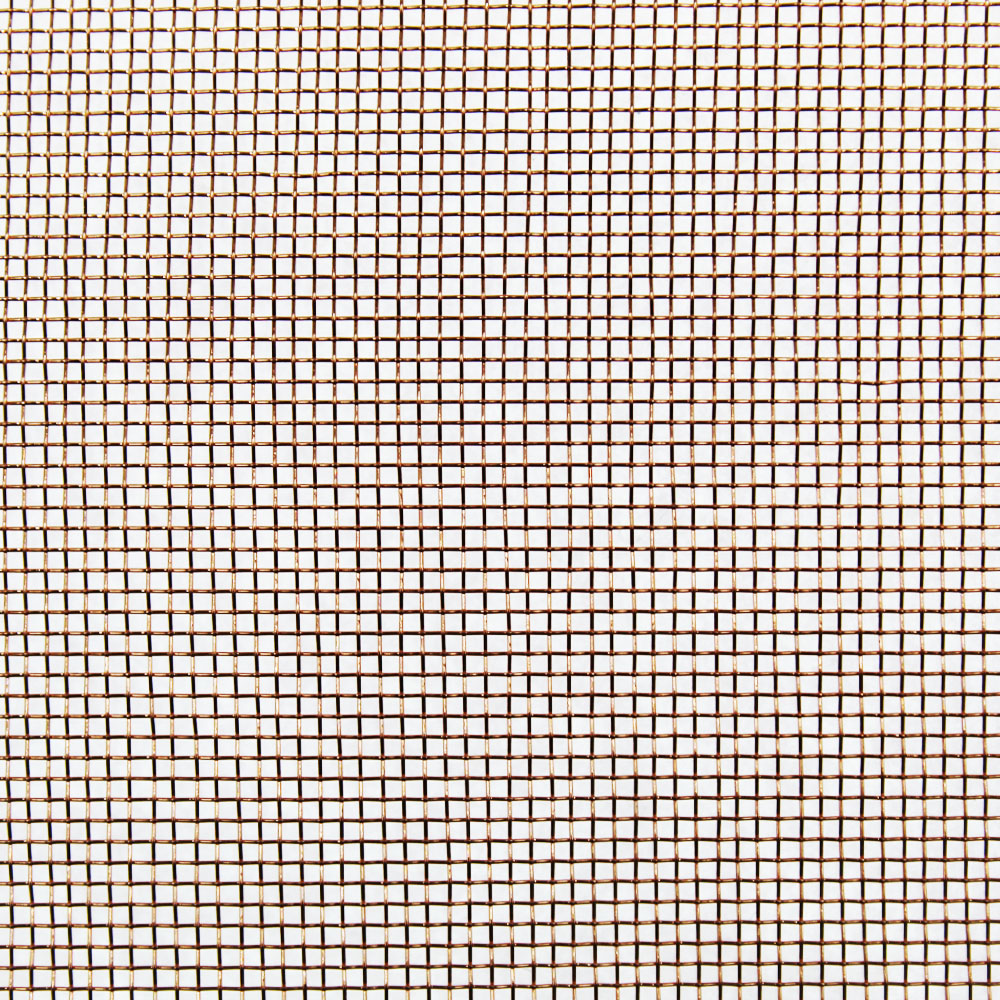

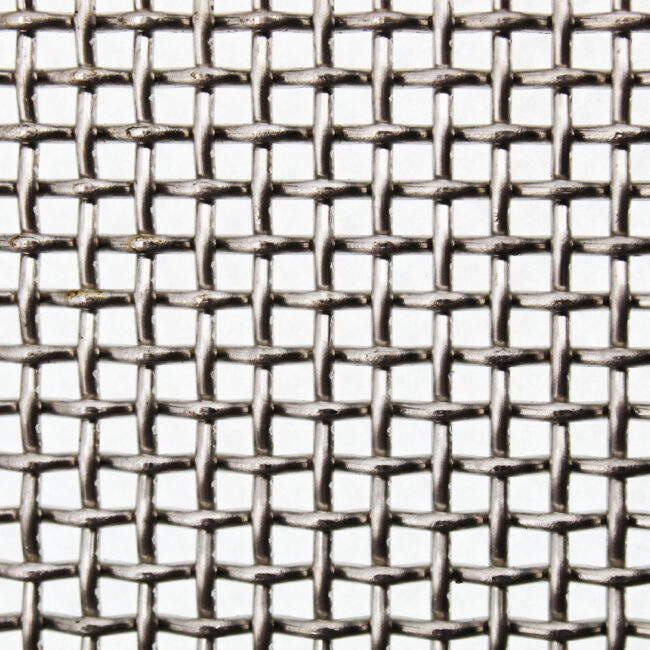

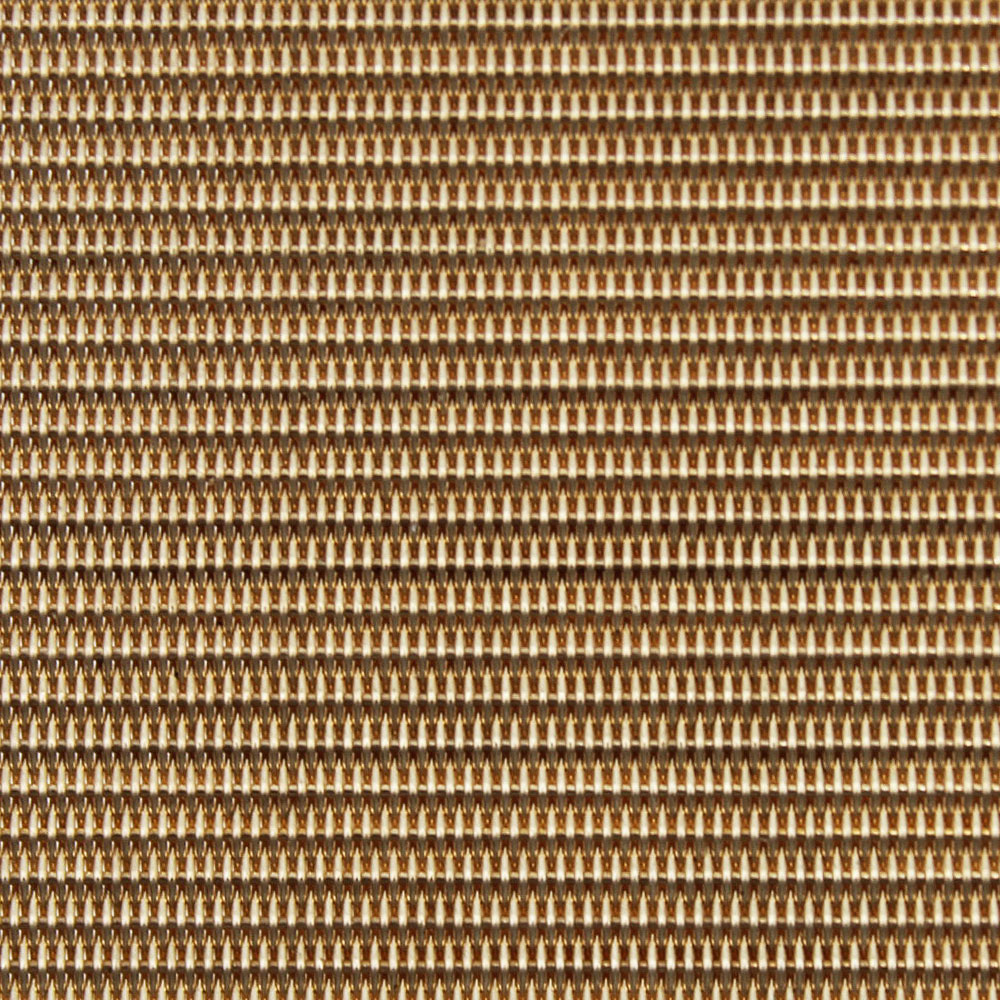

Woven mesh, created by weaving horizontal and vertical wires together, is particularly popular where precision and strength are required. With options in stainless steel, mild steel and other alloys, woven mesh offers consistent performance and durability in everything from fine filtration to heavy-duty separation. Products are available in standard rolls or bespoke cut-to-size panels to meet precise requirements.

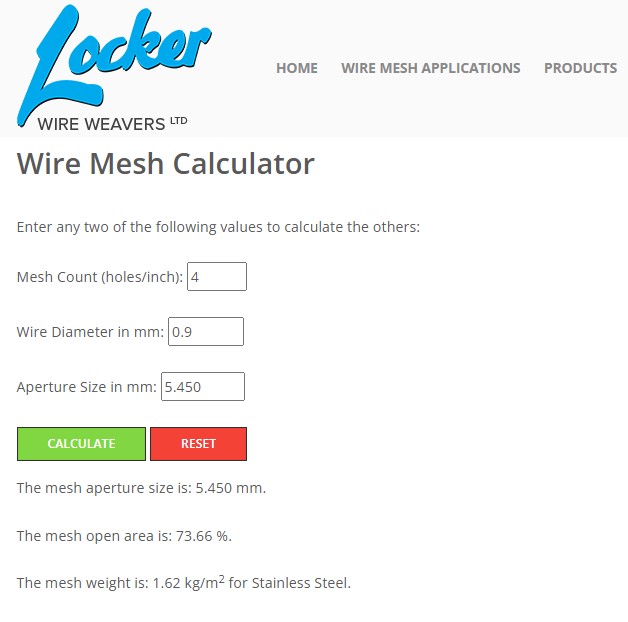

Accurate specification starts with understanding the relationship between mesh count, wire diameter and aperture. These parameters affect the flow rate, strength, visibility, and durability of the mesh. Our online mesh calculator makes it easy to find the right solution by inputting just two variables.

Locker Wire Weavers highlights the same importance of application-specific mesh selection. Their range of woven wire cloth is tailored to industrial filtration, screening and separation. They reinforce that aperture size directly affects throughput, particle retention and mechanical strength. Choosing the wrong aperture not only compromises performance but can also lead to higher maintenance costs and premature equipment wear.

With these considerations in mind, let’s explore how to determine the best aperture size for your specific use case and avoid common pitfalls along the way.

Factors to Consider When Selecting an Aperture Size

- Application Requirements

Identify the core purpose of your mesh. For filtration, choose a fine mesh that captures small particles effectively. For screening, larger openings enable greater material throughput, which is ideal for mining and aggregate industries. In safety and guarding, smaller openings prevent accidental contact with machinery and enhance worker protection. Precision applications like pharmaceutical sieving demand consistency in mesh dimensions to ensure product quality.

- Material Type

The type of metal used in the mesh affects both performance and longevity. Stainless steel offers superior corrosion resistance, making it suitable for harsh or wet environments. Mild steel is cost-effective for indoor applications where moisture and chemicals are limited. Additionally, consider high-tensile or galvanised steel for increased strength or durability in specific settings. The choice of material should align with environmental conditions and expected wear.

- Load and Strength Considerations

Evaluate the mechanical stress the mesh will endure. Tighter apertures and thicker wire diameters increase the mesh's strength and load-bearing capacity. For structural or vibrating applications like quarry screens, high-strength woven mesh is recommended. Conversely, delicate operations such as seed sorting benefit from finer, lighter meshes. Always ensure your chosen specification accounts for both static loads and dynamic stress.

- Environmental Conditions

Mesh used in extreme temperatures, moisture-rich or chemically aggressive environments must be highly durable. Stainless steel woven mesh is ideal for resisting corrosion in marine or chemical processing environments. For dusty, abrasive, or outdoor settings, reinforced or coated meshes can provide additional protection. Understanding the long-term exposure risks can guide both material and aperture decisions.

- Flow Rate and Pressure

Flow rate is crucial in filtration and drying processes. Larger openings increase airflow or liquid movement but can compromise filtering accuracy. In applications where fine filtration is required, such as water purification or chemical separation, smaller mesh apertures are necessary. Consider the balance between permeability and particle retention based on your operational requirements.

- Mesh Count and Wire Diameter

Mesh count (number of openings per inch) combined with wire diameter determines the open area percentage and mechanical strength. A higher mesh count with fine wire offers precision filtration but reduces flow. Lower mesh counts with thick wires allow for heavier throughput. Use Locker Wire Weavers’ mesh calculator to test combinations and select the most efficient and cost-effective option for your task.

Common Applications and Their Recommended Mesh Openings

Woven Mesh for Filtration

Ideal for sieving and filtering, woven mesh with fine apertures is used extensively in food production, pharmaceuticals, and water treatment. Typical sizes range from 0.05mm to 1.0mm depending on the material being filtered. In the food industry, meshes with apertures around 0.25mm are commonly used for flour sifting, while finer meshes around 0.1mm are essential in pharmaceutical applications to ensure high purity.

Screening in Mining and Quarrying

Heavy-duty screens use mesh with larger openings, often between 20mm and 50mm, to handle rock, gravel, and ore. Woven mesh offers strong wear resistance and longer lifespan. In mining operations, choosing the correct mesh aperture improves material separation efficiency and prolongs the service life of screens, reducing maintenance costs and downtime.

Safety, Guarding and Fencing

Mesh guards for machines or perimeter fences benefit from moderate openings, typically 10mm to 30mm. This prevents intrusion while maintaining visibility. Finer apertures, closer to 10mm, are often used for machine guards in manufacturing environments to prevent finger access, while larger sizes are suitable for perimeter security fencing in industrial premises.

Agricultural and Horticultural Uses

Woven mesh serves vital roles in sieves for seed grading, drying racks for produce, animal enclosures, and crop protection netting. Apertures between 2mm and 10mm are typical depending on the specific use. For example, 5mm apertures are used to protect crops from pests without impeding light and air flow, while stronger, larger apertures are suited for livestock fencing.

Manufacturing and Engineering

Woven wire mesh is critical for component separation, vibration screening, and protective shrouds in machinery. Apertures for these applications can vary widely, from less than 1mm for precision engineering to over 10mm for heavier manufacturing processes. Correct aperture selection ensures optimal machine efficiency and safe operational practices.

Architectural Applications

While not the focus here, it's worth noting that woven mesh is also used in some architectural projects where strength and airflow are required, such as ventilation grilles and protective cladding. Here, apertures are selected based on aesthetic as well as functional needs, often around 5mm to 20mm.

How to Use Locker Wire Weavers’ Mesh Calculator

Our online calculator simplifies aperture determination. Enter the mesh count and wire diameter, and it automatically computes the opening size and percentage of open area. This tool ensures accuracy and saves time when specifying industrial mesh.

This is a screenshot taken of an example of the use of the calculator. This mesh has 4 holes per linear inch and 0.9mm wire.

The aperture is therefore 5.45mm

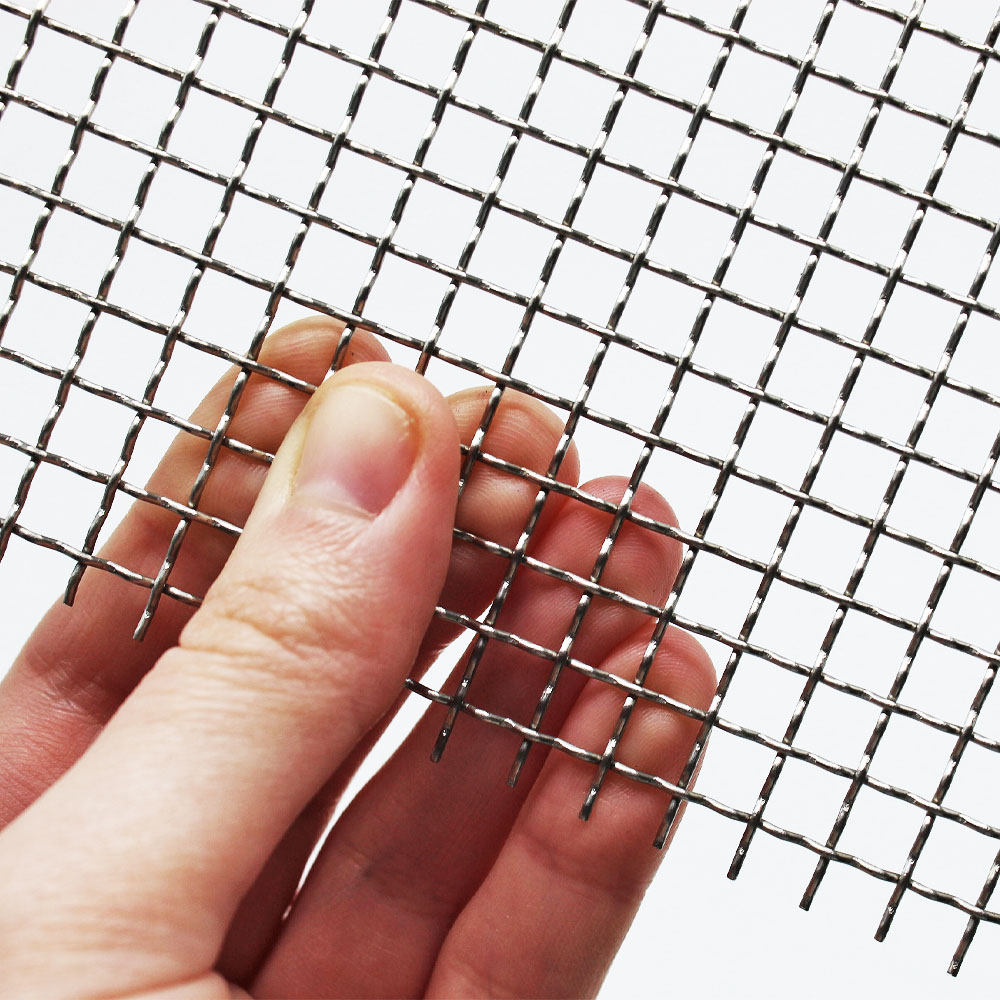

This is what 4 x 0.9mm stainless steel woven mesh looks like in comparison to the human hand.

As you can see the aperture size is fairly large:

Practical Tips for Choosing the Right Mesh Opening

- Consider exposure to dust, chemicals, and moisture

- Balance between flow rate and particle retention

- Choose stainless steel for corrosion resistance

- Use woven mesh where uniformity and precision are essential

- Don’t over-specify; excessive fineness adds cost and reduces flow

Mistakes to Avoid

- Ignoring wire gauge and structural requirements

- Choosing mesh without confirming environmental durability

- Overlooking how flow and pressure interact with aperture

FAQs

What is the difference between mesh count and aperture?

Mesh count is the number of openings per inch; aperture is the size of each opening.

Why choose woven mesh?

It offers uniform apertures, high strength, and excellent performance in filtration and separation.

Can mesh be custom made?

Yes. Locker Wire Weavers manufacture bespoke panels in a wide variety of aperture sizes and materials.

What happens if I pick the wrong mesh opening?

It could lead to reduced performance, higher maintenance costs, or safety failures.

Why Locker? Expertise Forged Over Generations

Founded in 1878, Locker Wire Weavers was a pioneer in wire weaving, reputedly the first to use steam-powered looms for industrial mesh production. Today, we continue to lead in:

- Technical advice and engineering support

- Stockholding of hundreds of mesh specifications

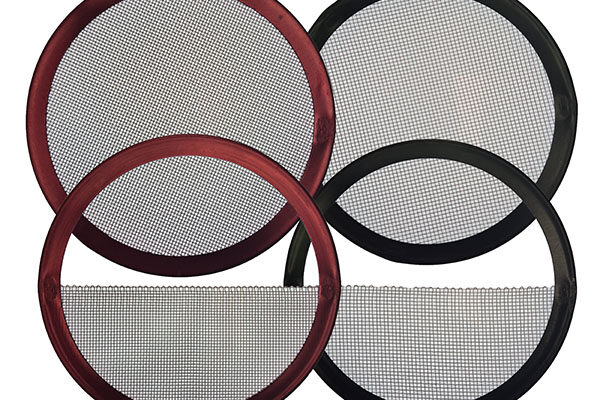

- Fabrication of complete filter assemblies and framed screens

All of our products are made under ISO 9001:2015-certified quality systems, and we are committed to exceeding industry expectations in every aspect of service and delivery.

Conclusion

Choosing the right mesh opening is essential for the success of your industrial or safety application. With expert advice and tools like the mesh calculator, Locker Wire Weavers helps ensure that your mesh is specified precisely to meet your operational requirements.

Visit Locker Wire Weavers to explore our full range of woven and welded mesh solutions.

Content Portfolio

- AWG and SWG Wire Gauges: Conversion to mm

- Leaf Filters for Industrial Filtration

- How to Choose the Right Aperture Size for Your Application

- ISO 4783 Explained: The Global Standard for Mesh Quality and Why It Matters

- Mesh Discs and Screens for Plastic Extruders

- Wire Mesh Disc and Filter Manufacturing

- Locker Pride in Manufacturing

- Brass Mesh Lighting Pendants