Key Benefits of Extruder Mesh Discs

- Ensure contaminant-free polymer melt

- Withstand high temperatures and pressures

- Reduce extrusion downtime and maintenance

- Extend life of downstream tooling

- Customisable in mesh size, shape, and frame type

What Are Extruder Mesh Discs?

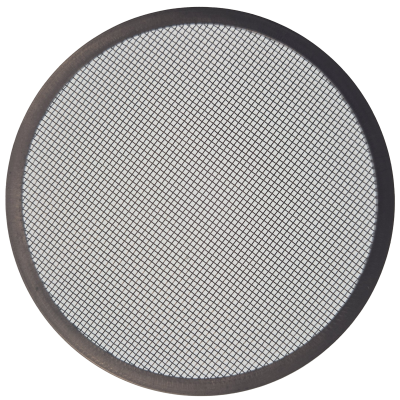

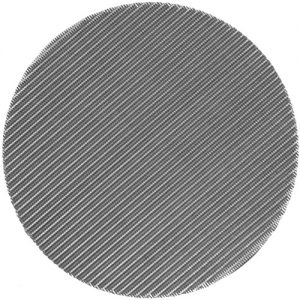

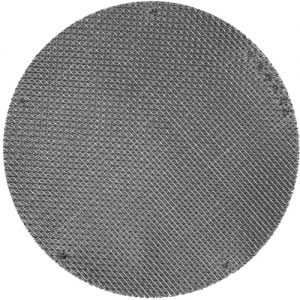

Extruder mesh discs are precision-engineered wire mesh filters used extensively in plastic, rubber, and synthetic fibre production. Their primary function is to remove impurities during the extrusion process, particularly in the melt phase, where any contamination can severely compromise the quality of the final product. By acting as a physical barrier against gels, burnt material, or unmelted polymer lumps, these discs ensure a consistent, defect-free output.

At Locker Wire Weavers Ltd, we have supplied extruder mesh discs to manufacturers across a wide range of sectors, including high-performance polymer producers, automotive component manufacturers, plastic recyclers, and medical-grade extrusion facilities. These clients turn to us not only for the quality of our wire mesh but for our ability to deliver fully customised, high-tolerance disc solutions suited to even the most demanding production environments.

How Extruder Mesh Discs Work

Positioned at the melt zone of an extruder, these discs trap foreign particles or degraded material that could compromise product quality or damage precision tooling. The mesh layers are carefully chosen to provide a balance between flow rate and filtration efficiency.

Why Choose Locker Wire Weavers for Extruder Mesh Discs?

With over 140 years of weaving expertise, Locker Wire Weavers Ltd offers unrivalled knowledge in wire mesh manufacturing. Our extruder screens and disc packs are tailored to client specifications and manufactured from the highest quality metals.

Clients come to Locker Wire Weavers for more than just mesh, they come for precision, trust, and problem-solving. We often hear from extrusion operators struggling with inconsistent flow rates, blocked dies, or unacceptable product variation. In these cases, our technical team works closely with their engineers to recommend or produce a tailored filtration solution.

Whether the goal is to improve throughput, reduce downtime, or meet stricter industry regulations, Locker’s extruder mesh discs deliver. Backed by more than 145 years of mesh manufacturing heritage, every disc we supply reflects our commitment to UK-engineered quality, rapid delivery, and dependable customer service.

Materials and Mesh Options

Locker stocks an extensive range of woven mesh in aperture sizes from 5 mm down to 1 micron, offering high open area for optimal flow, precise aperture control, resistance to corrosion and high temperatures, and custom diameters and shapes.

Applications of Extruder Mesh Discs

Extruder mesh discs are essential in plastic extrusion, rubber processing, synthetic fibre manufacture, recycling operations, and food and pharmaceutical-grade polymer filtering.

Custom Engineering Capabilities

Locker doesn’t just weave mesh – we fabricate complete solutions. Our in-house engineers provide design advice, welding, brazing, spot welding, press forming, and laser and air plasma cutting for intricate shapes.

Locker Quality and Delivery

Certified to ISO 9001:2015, Locker ensures repeatable performance and fast supply with large stockholding, quick turnaround for custom disc fabrication, and UK-based production and international shipping.

This commitment to quality and speed makes us the trusted filtration partner for extrusion operations across the UK and beyond.

FAQ: Extruder Mesh Discs

What Mesh Size Should I Use?

It depends on the type of contaminant and required flow rate. Locker’s team can help specify based on your process.

Can I Get Multi-Layer Discs in Different Meshes?

Yes, we offer layered screen packs with progressively finer meshes for staged filtration.

Do You Supply With Rims?

Absolutely – rims in aluminium, copper or stainless steel improve durability and handling.

Can You Make Custom Shapes?

Yes, we cut discs, rings and shaped parts to order – even complex designs via laser cutting.

Get In Touch with the UK's Trusted Mesh Filtration Partner

At Locker Wire Weavers Ltd, we don’t just supply extruder mesh discs — we engineer solutions that help manufacturers across the world maintain consistency, reduce downtime, and meet increasingly tight production standards.

Our clients rely on us for:

-

Bespoke mesh disc manufacturing to exact specifications

-

Rapid turnaround from quote to dispatch

-

Consistent, ISO 9001-certified quality backed by over 145 years of weaving expertise

-

Technical support from our in-house engineers who understand real production pressures

Whether you're trialling a new polymer grade, dealing with persistent extrusion blockages, or simply in need of a reliable supplier that delivers on time — every time — our team is here to support you.