Key Benefits of Leaf Filters

- High surface area for efficient filtration

- Lower operational costs through reusable media

- Robust construction for long service life

- Adaptable to liquids, gases, and complex processes

- Easy cleaning and maintenance

- Consistent filtration performance

What Are Leaf Filters?

Leaf filters are precision-engineered filtration units that use multiple mesh elements, known as filter leaves, mounted inside a pressure vessel. Each leaf consists of a rigid frame supporting woven wire mesh or synthetic media. Fluid passes through the mesh, trapping unwanted particles while allowing clean liquid or gas to flow. This modular design offers a large surface area in a compact unit, making leaf filters ideal for industries where reliability, cost-efficiency, and product quality are essential.

How Leaf Filters Work

Operating Principle

Filtration Cycle

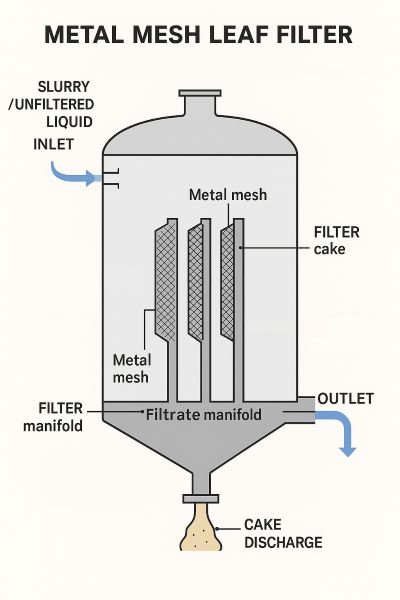

A number of filter leaves — typically vertical, flat, perforated metal plates covered with fine metal mesh, are mounted inside a pressure vessel.

The unfiltered liquid (slurry) enters the vessel and flows over and through the mesh-covered leaves.

The metal mesh acts as the filter medium, allowing the clear filtrate (liquid) to pass through the pores while retaining solid particles on the outer surface.

Cake Formation

As filtration continues, a filter cake (layer of solids) builds up on the mesh surface.

The cake itself becomes the primary filtering layer, improving filtration efficiency by capturing finer particles.

Filtrate Collection

The clean filtrate passes through the mesh and perforated plate into the hollow interior of each leaf.

From there, it flows into a central manifold and exits the vessel as filtered liquid.

Cake Discharge and Cleaning

When the pressure drop across the filter reaches a set limit, filtration stops.

The vessel is drained and depressurised.

The leaves are cleaned, usually by back-flushing, vibration, or compressed air to dislodge the cake.

The cake falls to the bottom of the vessel and is removed through a discharge port.

Advantages of Leaf Filters

1. High Filtration Efficiency

The stacked arrangement of leaves offers a large filtration surface within a compact unit. This maximises throughput while keeping the equipment footprint small.

2. Durability and Long Service Life

Constructed from stainless steel woven wire mesh, leaf filters withstand high pressure, high temperatures, and aggressive chemicals. Unlike disposable filter media, they are robust and reusable.

3. Cost Savings

Their reusability reduces ongoing consumable costs. Automated cake discharge systems further cut down on labour and downtime.

4. Flexibility in Design

Leaf filters can be customised to meet a wide range of process needs. From fine polishing of fluids to coarse particle separation, mesh specifications can be selected to suit.

5. Easy Cleaning

Filter leaves are simple to remove, clean, and reinstall. Many designs allow in-situ backwashing or vibration to remove filter cake, keeping processes running efficiently.

Why Choose Woven Wire Mesh for Leaf Filters?

At Locker Wire Weavers, we have supplied woven wire cloth for filtration since 1878. Woven mesh provides:

- Accurate aperture sizes for precise particle retention

- Smooth surfaces with no sharp edges, minimising product contamination

- High open area for maximum flow rate

- Temperature and pressure resistance unmatched by most synthetic media

These properties make woven wire the ideal choice for demanding industrial leaf filter applications.